OK, we need more details (dimensions). Please get with your friend and find out what the discrepancy was with the Lyman dies."a friend of mine called Lyman with specifications that are incorrect with the Lyman resizing die. Off my tongue, don't remember the exact details but Lyman's Tech said ... 'Oh shi**"

45-75 brass ?????

Forum rules

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

-

Leverluver

- Senior Levergunner

- Posts: 1000

- Joined: Sat Sep 08, 2007 4:02 pm

- Location: WY

-

Crotchety Old Grouch

- Levergunner

- Posts: 7

- Joined: Mon Oct 01, 2007 8:34 pm

Oct. 1, 2007

All of the following loads used reformed 348 Win Brass. I’ve noticed that the case capacity of my brass continues to grow. After 4 or 5 uses the capacity of my 348 cases has increased from 71.5 grains of water to 76.6... And the cases are approaching the dimensions shown in the drawing on Hobie’s site. That makes their capacity now 94.59% of the average 45-70 verses the 88.2% figure that I used in my original fuzzy logic attempt to use 45-70 data. Anyway, now that I have a Chronograph I’m also comparing the velocities I achieve with those published for the same bullet and powder in a 45-70. I figure that the same bullet propelled by the same powder at the same speed from a similar case capacity should generate roughly, ROUGHLY the same chamber pressure. I know there are a lot of variables like barrel length etc. but hey, it’s just an guestament to keep me below 20,000 CUP. My fastest load today with the Lyman bullet was 1526fps. The 48th edition Lyman handbook shows a 45-70 IMR 3031 load with that bullet going 1532fps at 15,300 CUP, so I figure I’m safe. That load used 47.5gr mine used 44 gr.

There was no leading or signs of adverse pressure, and there was much less (hardly any) unburned powder left in the barrel compared to when I used 300gr. bullets.

Today’s Results

Chaparrel NWMP SRC 45-75Win.

22" round Barrel

330 Lyman HP, .Sized to 459 dia. SPG lube, Powder IMR 3031, Primer, Rem. 9 ½

Charge, 42.5 gr

#1, 1425

#2, 1426

#3, 1443

#4, 1433

#5, 1425

Lo 1425

Hi 1443

Av 1430

ES 17.85

SD 7.81

Charge, 43 gr.

#1 1450

#2 1468

#3 1470

#4 1405

#5 1472

Lo 1405

Hi 1492

Av 1457

ES 67.23

SD 28.23

Charge, 43.5

#1 1439

#2 1437

#3 1439

#4 1473

#5 1493

Lo 1437

Hi 1493

Av 1456

ES

SD ? (pushed the wrong button)

Charge, 44.0 Gr

#1 1506

#2 1440

#3 1448

#4 1526

#5 1474

Lo 1440

Hi 1526

Av 1479

ES 86.24

SD 36.89

Chaparrel NWMP SRC 45-75Win.

22" round Barrel

340gr, from Lee Mold .Sized to 459 dia. SPG lube, Powder IMR 3031, Primer, Rem. 9 ½

Charge, 42.5 gr

#1 1450

#2 1439

#3 1461

#4 1458

#5 1441

Lo 1439

Hi 1461

Av 1450

ES 22.77

SD 9.79

Charge 43.0 gr.

#1 1462

#2 1458

#3 1443

#4 1394

#5 1480

Lo 1394

Hi 1480

Av 1447

ES 85.44

SD 32.63

Charge, 43.5

#1 1480

#2 1476

#3 1461

#4 1445

#5 1495

Lo 1445

Hi 1495

Av 1473

ES 49.99

SD 20.09

Charge, 44.0

#1 1510

#2 1492

#3 1504

#4 1526

#5 1511

Lo 1492

Hi 1526

Av 1508

ES 33.87

SD 12.32

This is some data from about a month ago.

Chaparrel NWMP SRC 45-75Win.

22" round Barrel

300 gn TC bullet , .459 dia. Powder 5744, Primer, Rem. 9 ½

Charge 21.5 gr

Av Vel, 1098fps

ES. 34.87

SD, 13.07

Charge, 22.0gr

Av Vel,1097fps

ES, 14.11

SD, 5.74

Charge, 22.5 gr

Av Vel, 1131fps

ES, 23.29

SD, 10.44

Charge, 23.5 gr

Av Vel, 1172rps

ES, 39.41

SD, 15.36

All of the following loads used reformed 348 Win Brass. I’ve noticed that the case capacity of my brass continues to grow. After 4 or 5 uses the capacity of my 348 cases has increased from 71.5 grains of water to 76.6... And the cases are approaching the dimensions shown in the drawing on Hobie’s site. That makes their capacity now 94.59% of the average 45-70 verses the 88.2% figure that I used in my original fuzzy logic attempt to use 45-70 data. Anyway, now that I have a Chronograph I’m also comparing the velocities I achieve with those published for the same bullet and powder in a 45-70. I figure that the same bullet propelled by the same powder at the same speed from a similar case capacity should generate roughly, ROUGHLY the same chamber pressure. I know there are a lot of variables like barrel length etc. but hey, it’s just an guestament to keep me below 20,000 CUP. My fastest load today with the Lyman bullet was 1526fps. The 48th edition Lyman handbook shows a 45-70 IMR 3031 load with that bullet going 1532fps at 15,300 CUP, so I figure I’m safe. That load used 47.5gr mine used 44 gr.

There was no leading or signs of adverse pressure, and there was much less (hardly any) unburned powder left in the barrel compared to when I used 300gr. bullets.

Today’s Results

Chaparrel NWMP SRC 45-75Win.

22" round Barrel

330 Lyman HP, .Sized to 459 dia. SPG lube, Powder IMR 3031, Primer, Rem. 9 ½

Charge, 42.5 gr

#1, 1425

#2, 1426

#3, 1443

#4, 1433

#5, 1425

Lo 1425

Hi 1443

Av 1430

ES 17.85

SD 7.81

Charge, 43 gr.

#1 1450

#2 1468

#3 1470

#4 1405

#5 1472

Lo 1405

Hi 1492

Av 1457

ES 67.23

SD 28.23

Charge, 43.5

#1 1439

#2 1437

#3 1439

#4 1473

#5 1493

Lo 1437

Hi 1493

Av 1456

ES

SD ? (pushed the wrong button)

Charge, 44.0 Gr

#1 1506

#2 1440

#3 1448

#4 1526

#5 1474

Lo 1440

Hi 1526

Av 1479

ES 86.24

SD 36.89

Chaparrel NWMP SRC 45-75Win.

22" round Barrel

340gr, from Lee Mold .Sized to 459 dia. SPG lube, Powder IMR 3031, Primer, Rem. 9 ½

Charge, 42.5 gr

#1 1450

#2 1439

#3 1461

#4 1458

#5 1441

Lo 1439

Hi 1461

Av 1450

ES 22.77

SD 9.79

Charge 43.0 gr.

#1 1462

#2 1458

#3 1443

#4 1394

#5 1480

Lo 1394

Hi 1480

Av 1447

ES 85.44

SD 32.63

Charge, 43.5

#1 1480

#2 1476

#3 1461

#4 1445

#5 1495

Lo 1445

Hi 1495

Av 1473

ES 49.99

SD 20.09

Charge, 44.0

#1 1510

#2 1492

#3 1504

#4 1526

#5 1511

Lo 1492

Hi 1526

Av 1508

ES 33.87

SD 12.32

This is some data from about a month ago.

Chaparrel NWMP SRC 45-75Win.

22" round Barrel

300 gn TC bullet , .459 dia. Powder 5744, Primer, Rem. 9 ½

Charge 21.5 gr

Av Vel, 1098fps

ES. 34.87

SD, 13.07

Charge, 22.0gr

Av Vel,1097fps

ES, 14.11

SD, 5.74

Charge, 22.5 gr

Av Vel, 1131fps

ES, 23.29

SD, 10.44

Charge, 23.5 gr

Av Vel, 1172rps

ES, 39.41

SD, 15.36

COG,

Thanks for that info. I've got both molds and it will be helpful.

The .50 Alaskan cases are about the same as the .348 Win just easier/quicker to form.

Thanks for that info. I've got both molds and it will be helpful.

The .50 Alaskan cases are about the same as the .348 Win just easier/quicker to form.

- Rough trim .22" from .50 Alaskan case

- Chamfer case

- Lube as usual for full length resizing

- Full length size

- Anneal

- Run into case mouth expansion die

- Final trim

- Prime

- Load

- Shoot

Last edited by Hobie on Sat Oct 06, 2007 12:10 pm, edited 1 time in total.

Sincerely,

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Lyman 456192 350 IMR 4198 24.0 1380 1480

Last edited by Hobie on Sat Oct 06, 2007 12:14 pm, edited 1 time in total.

Sincerely,

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

-

Leverluver

- Senior Levergunner

- Posts: 1000

- Joined: Sat Sep 08, 2007 4:02 pm

- Location: WY

Hobie

I did a search on this forum (and your blog) and didn't come up with what I wanted. It is probably on the old forum that I have zero success searching. What I need is the head and shoulder diameter of factory TenX loaded ammo. Also the distance from the front face of the rim to the ege of the shoulder. I want to order the reamer and I want to accomplish two things; reduced over-working of the brass by sizing and reinflating in the chamber, plus still be able to chamber factory ammo (if I ever sell the rifle). Do you (or anyone else) have that info somewhere in your 45-75 repository?

Mike

I did a search on this forum (and your blog) and didn't come up with what I wanted. It is probably on the old forum that I have zero success searching. What I need is the head and shoulder diameter of factory TenX loaded ammo. Also the distance from the front face of the rim to the ege of the shoulder. I want to order the reamer and I want to accomplish two things; reduced over-working of the brass by sizing and reinflating in the chamber, plus still be able to chamber factory ammo (if I ever sell the rifle). Do you (or anyone else) have that info somewhere in your 45-75 repository?

Mike

Well, Mike, TenX tells me that they use Jamison brass and they, consequently, don't have ammo. My order is still to be filled. So, I guess that those who use it, like SixgunShorty haven't seen your request. He had some and was using it.

FWIW, I loaded and measured my brass made from .50-90 Sharps and .50 Alaskan at the neck with a .458" bullet seated (I haven't got a .459" bullet to try.) and got .4795"-.480" and .4845"-.485" respectively. Both feed in my gun.

I've got to tell you, I prefer the .50 AK brass for ease of forming. As it should be, it is pretty darn close to .348 Win brass in final dimensions (after forming). That might not work for everyone.

FWIW, I loaded and measured my brass made from .50-90 Sharps and .50 Alaskan at the neck with a .458" bullet seated (I haven't got a .459" bullet to try.) and got .4795"-.480" and .4845"-.485" respectively. Both feed in my gun.

I've got to tell you, I prefer the .50 AK brass for ease of forming. As it should be, it is pretty darn close to .348 Win brass in final dimensions (after forming). That might not work for everyone.

Sincerely,

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

-

Leverluver

- Senior Levergunner

- Posts: 1000

- Joined: Sat Sep 08, 2007 4:02 pm

- Location: WY

Thanks Hobie. I'm pretty sure someone has already posted the Jamison info on the old Leverguns or maybe SASS and I just thought that you might have saved it. I did save the SASS links but they are no longer available and you can't even Google the old leverguns anymore; well at least you can't open it when you do find something. I'll see if Jamison will give out the info.

Got the range for a quick session with my fireforming load and half a box of the Buffalo Arms ammo. Interesting.

Lessons learned:

Lessons learned:

- anneal brass before forming otherwise some will split on firing

- .50-90 Sharps brass will feed two rounds from the "magazine", no more, as the rim is too big to enter the mag tube! (now why didn't I think to check that)

- even fireforming loads shoot high at 50 yards, 10" high! They were still high at 150 yards!

- Buffalo Arms ammo was only 5-6" high at 50 yards.

Sincerely,

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

-

Leverluver

- Senior Levergunner

- Posts: 1000

- Joined: Sat Sep 08, 2007 4:02 pm

- Location: WY

If the purpose is solely to keep the cases from splitting on the first firing, maybe annealing AFTER the forming would do a better job. Annealed before is still going to get work hardened in the process of forming. After and the stresses would be relieved and the case would easily take the shape of the chamber. Just thinking.....always dangerous

You might be right. But annealing is needed. I thought the Starline brass was pretty hard during the first trim and annealing DID cross my mind but it is such a short trip that it left no mark and I didn't do it. I will now.

The rifle ready to go...

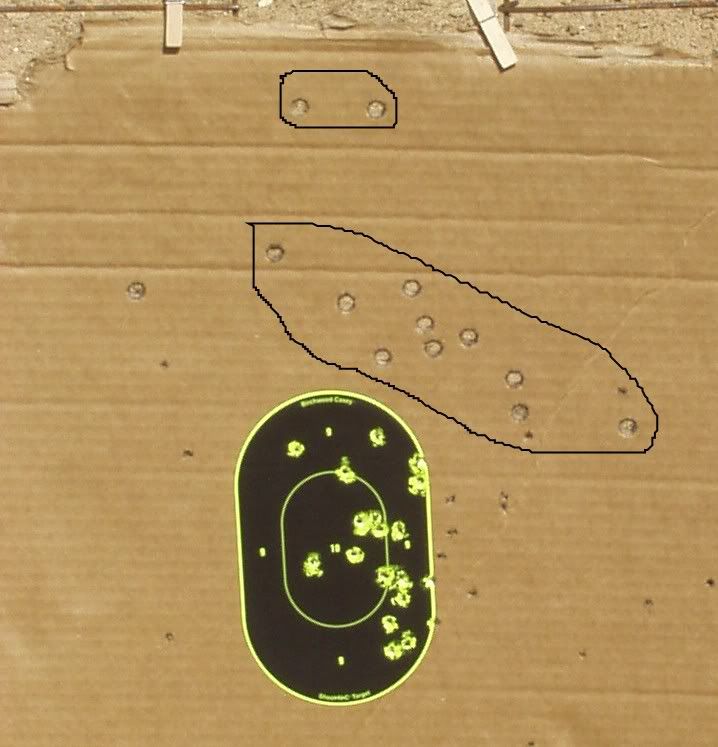

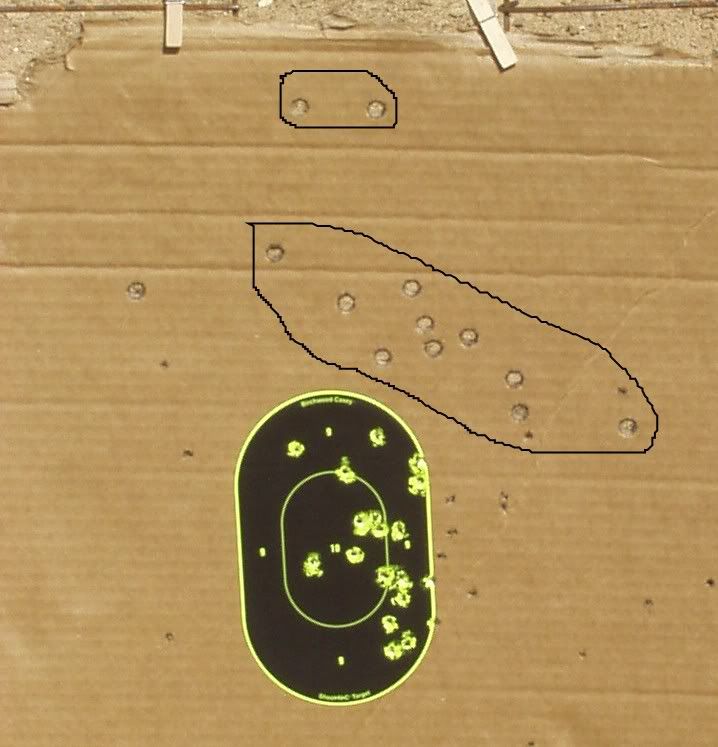

The split cases with fired reformed .50-90, .50 Alaskan, split cases, and "fire-forming" load (.50 Alaskan reformed)

Big "group" is the Buffalo Arms ammo. Aiming point is the 10 in the elongated bullseye. Small circle of two rounds is the only two of the fireforming loads aimed at the 10 that stayed on the backer...

Action aftermath...

The rifle ready to go...

The split cases with fired reformed .50-90, .50 Alaskan, split cases, and "fire-forming" load (.50 Alaskan reformed)

Big "group" is the Buffalo Arms ammo. Aiming point is the 10 in the elongated bullseye. Small circle of two rounds is the only two of the fireforming loads aimed at the 10 that stayed on the backer...

Action aftermath...

Sincerely,

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

-

Leverluver

- Senior Levergunner

- Posts: 1000

- Joined: Sat Sep 08, 2007 4:02 pm

- Location: WY

WOW,  you've got more problems than a hardened neck from just the forming process. The body shouldn't have been work hardened to any great degree and it is split also; obviously from trying to conform to the oversized (in relation to the brass) chamber. I've never seen new brass split like that (well I have but it had a kangaroo on it, so it was expected). I've never tried to anneal down that far and that close to the head. I suppose it can be done but it will be touchy. Anneal with only 1/4" of water in the pan maybe. I don't care if factory ammo won't chamber or not. I'm not making my reamer near that large. BTW, Jamison never called back with dimensions.

you've got more problems than a hardened neck from just the forming process. The body shouldn't have been work hardened to any great degree and it is split also; obviously from trying to conform to the oversized (in relation to the brass) chamber. I've never seen new brass split like that (well I have but it had a kangaroo on it, so it was expected). I've never tried to anneal down that far and that close to the head. I suppose it can be done but it will be touchy. Anneal with only 1/4" of water in the pan maybe. I don't care if factory ammo won't chamber or not. I'm not making my reamer near that large. BTW, Jamison never called back with dimensions.

-

Crotchety Old Grouch

- Levergunner

- Posts: 7

- Joined: Mon Oct 01, 2007 8:34 pm

I've fireformed over 100 winchester 348 cases so far and have'nt split one yet. That Starline must be real hard and brittle. Maybe if you used a lighter load and a lead bullet you could avoid that. Hell it takes me at least two or three firerings to completly swell up those 348 cases anyway.

I just finished making an attachment for my Lyman 330gr hollow point mold that lets me adjust the deepth of the hollow point down to just a dipple of none at all. The bullets in the w/o the hollow point is 343gr.

All right, I give up, How do you guye get your pictures to show on your post?

Here is a link to the photos of the mod and the before and after bullets. The before are 322gr the after is 343gr. Guess I need another trip to the range.

http://groups.msn.com/GOFWGPinMakin/4575.msnw?Page=1

(Hobie) the last two pics I did for you, Thats the belly of my NWMP CArbine your looking at.

I just finished making an attachment for my Lyman 330gr hollow point mold that lets me adjust the deepth of the hollow point down to just a dipple of none at all. The bullets in the w/o the hollow point is 343gr.

All right, I give up, How do you guye get your pictures to show on your post?

Here is a link to the photos of the mod and the before and after bullets. The before are 322gr the after is 343gr. Guess I need another trip to the range.

http://groups.msn.com/GOFWGPinMakin/4575.msnw?Page=1

(Hobie) the last two pics I did for you, Thats the belly of my NWMP CArbine your looking at.

-

Crotchety Old Grouch

- Levergunner

- Posts: 7

- Joined: Mon Oct 01, 2007 8:34 pm

Hobie, the epoxied on bead on my front sight finally feel off some place so my carbine is shooting high too. The best load I had yesterday was the 42.5 gr of 3031 with the 330 gr Lyman bullet. It gave me a two inch group at 50 yards 9" high. Now 2" at 50 yards doesn’t sound that good but with my old eyes and that itty bitty tapered post front sight it is. After a few seconds that top of the sight starts too disappear and then it just keeps getting shorter and shorter. Now 3 of the 5 shots in that group where within 3/4" but I can’t swear that they were the first three but I think they were (that’s my story and I’m stickin to it).

Anyway I input the data from yesterdays range session into the ballistic calculator at the below link. 1430fps, 330gr bullet, Bal coif .274. The table gave me the following info based on the given info. Acually it gives it to you in 10 yard increments but I’m way too lazy to do that much typing. Anyway with this info. I think that it wouldn’t be that hard to deal with the trajectory. You just have to remember that your 9" high at 50, about 14 high at 100 and at 150 and right on at 225. If your good at distances I think it wouldn’t hard to hunt with, in fact I’m taking it out tomorrow scouting for deer and checking on the elk heards..

Range........Velocity........Impact.......Energy

...0.............1430............-0.5 ...........1498

..50............1329.............9.32...........1294

100............1241............14.19...........1129

120............1209............14.6.............1071

150............1166............13.41............996

200............1104.............6.22.............893

225............1077...............0................844

http://www.handloads.com/calc/

Anyway I input the data from yesterdays range session into the ballistic calculator at the below link. 1430fps, 330gr bullet, Bal coif .274. The table gave me the following info based on the given info. Acually it gives it to you in 10 yard increments but I’m way too lazy to do that much typing. Anyway with this info. I think that it wouldn’t be that hard to deal with the trajectory. You just have to remember that your 9" high at 50, about 14 high at 100 and at 150 and right on at 225. If your good at distances I think it wouldn’t hard to hunt with, in fact I’m taking it out tomorrow scouting for deer and checking on the elk heards..

Range........Velocity........Impact.......Energy

...0.............1430............-0.5 ...........1498

..50............1329.............9.32...........1294

100............1241............14.19...........1129

120............1209............14.6.............1071

150............1166............13.41............996

200............1104.............6.22.............893

225............1077...............0................844

http://www.handloads.com/calc/

Last edited by Crotchety Old Grouch on Wed Oct 03, 2007 11:36 pm, edited 1 time in total.

Mike, here's the only information I have on Jamison/TenX cases:

Rim Thickness

Original cases - 056

Jamison - TenX - 057

Buffalo Arms - 057

348 Resized - 062

Base Diameters

Original cases - 621

Jamison - TenX - 613

Buffalo Arms - 605

348 Resized - 602

But, IMHO, I don't believe you want to use any Jamison data. Chaparral, Italy is now producing 45-75 brass and it is NOT to Jamison Spec's!

Send me your email and I'll mail you the complete blueprint of the case they are making. It is a copy of a 1918 WRC case

Rim Thickness

Original cases - 056

Jamison - TenX - 057

Buffalo Arms - 057

348 Resized - 062

Base Diameters

Original cases - 621

Jamison - TenX - 613

Buffalo Arms - 605

348 Resized - 602

But, IMHO, I don't believe you want to use any Jamison data. Chaparral, Italy is now producing 45-75 brass and it is NOT to Jamison Spec's!

Send me your email and I'll mail you the complete blueprint of the case they are making. It is a copy of a 1918 WRC case

Regards

John

John

Starline brass as a reputation as being harder than normal. Work it a bit (although it readily formed) and you get brittle, or so it seems. 8 cases of 20 split. That's a $6.96 lesson. MOST all the splits seem to start in the shoulder so you probably don't need to anneal down to the head.

The type of bullet (jacketed vs. cast) and this mild load are not the cause of the splits. That simply is not logical. The splits are the result of pressure (and not excessive pressure) in a too brittle case which is trying to expand in the chamber.

I haven't had a single reformed .348 Winchester case split.

I think the .50 Alaskan case is best choice for conversion just because of ease in forming. I'm going to try a batch annealed before forming and then a batch annealed after forming. I have the cases, might as well see which is best.

I see we are getting similar trajectories and POI using the issue sights. If the manufacturer duplicated the dimensions correctly then one has to wonder if Winchester deliberately did this to "increase" the usable range for most users (military users anyway) because those trajectories work for shooting at standing soldiers (or on horse) coming right at you. Just hold center-of-mass and you'll get hits on out there! That is not how we do it, of course, so we need to make modifications. For me, 3" high at 100 would probably work and the limited range my range estimation and the trajectory would give me is of no consequence. I'm hoping that moving to a tang peep will allow me to correct that.

Now, have you weighed these things? Can you imagine carting enough ammo around on your horse (or mule) to engage Apaches a way out there in the boonies? I can easily see how an individual Mountie or Scout using one of these rifles could have run into ammo re-supply problems.

The type of bullet (jacketed vs. cast) and this mild load are not the cause of the splits. That simply is not logical. The splits are the result of pressure (and not excessive pressure) in a too brittle case which is trying to expand in the chamber.

I haven't had a single reformed .348 Winchester case split.

I think the .50 Alaskan case is best choice for conversion just because of ease in forming. I'm going to try a batch annealed before forming and then a batch annealed after forming. I have the cases, might as well see which is best.

I see we are getting similar trajectories and POI using the issue sights. If the manufacturer duplicated the dimensions correctly then one has to wonder if Winchester deliberately did this to "increase" the usable range for most users (military users anyway) because those trajectories work for shooting at standing soldiers (or on horse) coming right at you. Just hold center-of-mass and you'll get hits on out there! That is not how we do it, of course, so we need to make modifications. For me, 3" high at 100 would probably work and the limited range my range estimation and the trajectory would give me is of no consequence. I'm hoping that moving to a tang peep will allow me to correct that.

Now, have you weighed these things? Can you imagine carting enough ammo around on your horse (or mule) to engage Apaches a way out there in the boonies? I can easily see how an individual Mountie or Scout using one of these rifles could have run into ammo re-supply problems.

Sincerely,

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Hobie, if I may ... from the looks of the splits, the fps and using copper clad bullets - my suggestion would be to load up some annealed brass with 55-60gr of either Fg or FFg powder and a 300gr cast bullet. The pressure curve will not be a long duration curve and the psi will be less than the smokeless.

Appears to be a high pressure being created in the case using the CC bullets and I presume the cases are crimp.

Using 348's - annealed - Not Fireformed and black powder: nicely shaped brass to the chamber and no splits.

Appears to be a high pressure being created in the case using the CC bullets and I presume the cases are crimp.

Using 348's - annealed - Not Fireformed and black powder: nicely shaped brass to the chamber and no splits.

Regards

John

John

-

Leverluver

- Senior Levergunner

- Posts: 1000

- Joined: Sat Sep 08, 2007 4:02 pm

- Location: WY

John Boy Thanks for the dimensions. I thought that was you that posted them before but all those old threads have vanished. Also thanks for the offer of the drawing but I have made up my mind. I will size cases and spec the reamer to match whatever comes out of the die. I had thought that if they were close, maybe I could spec it to also (just barely) accept factory ammo. I've let that concern go by the wayside. I will be putting a lot into this rifle (Turnbull included) and won't be getting rid of it. After I'm dead, I don't really care whether some other ammo chambers or not. What I care about now is that the rifle accepts the casings that I make and those casings last a long time. If the chamber is a standard .003" to .004" over the sized case in head, shoulder, and neck dimensions, the cases will not be stressed by over inflating and then sizing back down, not to mention the dies and chambers of factory offerings not having the same shoulder location. I'm also going to head space the barrel for the standard (~.065) rim thickness so I don't have to screw with that. Now that all the mental machinations are over with; on with the project.

Mike

Mike