Case-hardening ?

Forum rules

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

Welcome to the Leverguns.Com General Discussions Forum. This is a high-class place so act respectable. We discuss most anything here other than politics... politely.

Please post political post in the new Politics forum.

Case-hardening ?

How do you case-harden metal ,and what advantaged does it have over other processes, can you have a gun case-harden after purchase just to get that case-harden look ( colors ) ?

Re: Case-hardening ?

Check Doug Turnbull's website. He is the man when it comes to traditional casehardening. I have 3 USFA's that he did and they are beautiful. I think, but have nothing to support it, theat he does the casehardening for Colt. That it just a wild guess, but new Colts have the same rich hue that he does. My eye isn't experienced when it comes to this, but it does look the same.

Courage is being scared to death...and saddling up anyway

Re: Case-hardening ?

I don't know exactly how it's done, but true color case hardening is a heat treating process, IIRC. There are also chemical processes that produce similar results, and it's what a lot of the factories are doing to case harden their guns. It is cheaper and less time consuming than the heat treating method. Some of the chemical case hardening products are better than others. Brownells carries these products, and I would assume Midway does also. They sell DIY at home kits, but I can't speak as to how well they work. Hope that helps. Someone more knowledgeable about the subject will hopefully chime in shortly.

"If ye love wealth greater than liberty, the tranquility of servitude greater than the animating contest for freedom, go home from us in peace. We seek not your counsel, nor your arms. Crouch down and lick the hand that feeds you; and may posterity forget that ye were our countrymen" - Samuel Adams

- Griff

- Posting leader...

- Posts: 21395

- Joined: Sat Mar 31, 2007 4:56 pm

- Location: OH MY GAWD they installed a STOP light!!!

Re: Case-hardening ?

Case hardening: Using heat and cooling to condense the outside surface of the metal. i.e. hardening the surface. Color case hardening is the use of different materials as the heat conducting material to obtain differences in color of the treated surface. i.e., bone and charcoal. There's probably a LOT more involved in the actual chemical and metallurgical science of it... but hey, that's the simplistic answer my teacher thought I was capable of understanding.

Case Hardening

The following is a composite of two excellent posts on case hardening by subscribers Bruce Conner and Ward French.

It can be found at: http://members.aol.com/illinewek/faqs/case.htm

For readers wishing to pursue colour case hardening further, I strongly recommend a series of two articles by Mr. Oscar Gaddy on the subject, found in the winter 1996 and spring 1997 issues of the Double Gun Journal.

Bruce begins:

Case hardening involves putting carbon (or a combination of carbon and nitrogen) into the surface of the steel to make it a high-carbon steel which can be hardened by heat treatment, just as if it were tool steel or any other high carbon steel. Only the outer skin gets hard this way, the center is still tough and malleable. This makes for a strong part with a tough surface.

Ward continues:

Low carbon steel, i.e. steel with about 20 points or less of carbon, cannot be made to harden by heating and quenching, as higher carbon steels can. Low carbon steels are tough, soft and flexible. They wear quickly and batter easily.

Many parts, including gun actions in days gone by, were made with low carbon steel. It was cheap, strong and easy to machine. Unfortunately it would not stand up to the battering of use in the field. Case hardening added carbon to the surface skin of the steel part and left it in a state which could be hardened by quenching.

To case harden a part (the process is also known as pack hardening) the finished low carbon steel part is placed in a sealed container, packed with a high carbon compound. In the old days this was simply animal hide or bone. The container filled with parts and carbon bearing material was brought to a red heat and held at that temperature for a time determined by the size of the part. The time might be from a half hour up to several hours. As the bone or hide became carbon in the container, and a carbon rich gas formed, some of the carbon would infuse into the surface of the steel. Over time this would penetrate several thousandths of an inch, producing a high carbon surface on the low carbon steel part.

At the proper time the container is removed from the furnace and the contents dumped into a quenching bath, usually water with perhaps a surface coat of oil to lessen the shock of the quench. The high carbon surface skin becomes glass hard, but the low carbon body of the piece remains soft and very ductile and able to resist shock. Properly done it made a simple and very durable system for treating metal action parts.

Colors are produced when the steel surface is cooled unevenly, capturing the natural blues, oranges and yellows of cooling steel. Several methods are employed to do this. Stevens moved the parts into the quench in a jerky fashion, producing a barred effect of color. Perazzi did the same. In the London trade the quench bath, usually a barrel with soft water and a skim of oil, was agitated by stirring, or with bubbles of air, producing a mottled effect on the steel.

Bruce adds:

Color case hardening is done much the same way except that generally only leather and bone are used as the carbon source. I don't know why this works better than charcoal, but it does. You get more brilliant colors with them. The other thing you do is modify the quenching bath. You need a source of bubbles. LOTS of bubbles to really rile up the quench bath. Adding a bit of potassium nitrate to the water increases the brilliance of the colors as well, but isn't a requirement. You have to watch the temperature more closely with color case hardening or the colors won't come out well. Don't go over 1350 F.

Kasenit and similar compounds are a lot easier to use and you can just use a torch. You heat the part up red, dunk it into the Kasenit compound and get a good coating of it sticking to the steel in the places you want hardened. Then reheat it up to a good red and quench it in water. This can be repeated to increase the depth of the case hardening. It works very well and is quite fast, but leaves a kind of dull grey color to the surface. For parts that are internal it works great and if you make the hardening deep enough, you can polish the metal and still have a hard surface.

Ward continues:

The colors have nothing to do with the effectiveness of the case hardening. Many, if not most, parts are hardened without colors. The surface takes on a dull gray look. The London makers usually polish this surface bright. It is glass hard, but without the decorative affect of the colors.

Anyone who has a case colored part should be aware that colors will fade on exposure to direct sunlight over an extended time period. Parts must be protected. Clear fingernail polish or a similar lacquer will protect the surface and a gun case or cabinet will do the rest. Case hardening was widely used on all lock parts except springs, and the process could be carried out even on the frontier with a minimum of equipment and knowledge.

Good shooting,

Ward and Bruce

Walter Taber

- Houston, Texas

Last edited by Griff on Fri May 28, 2010 10:45 am, edited 1 time in total.

Griff,

SASS/CMSA #93

NRA Patron

GUSA #93

There is a fine line between hobby & obsession!

AND... I'm over it!!

No I ain't ready, but let's do it anyway!

SASS/CMSA #93

NRA Patron

GUSA #93

There is a fine line between hobby & obsession!

AND... I'm over it!!

No I ain't ready, but let's do it anyway!

Re: Case-hardening ?

Our own Mike Hunter does color-case as well.

Originally, case-hardening was done to provide a hard surface with shock resistant core OR a hardened surface on a relatively inexpensive type of steel. The colors and form of the colors are a result of the method used. Color case has become such a traditional finish that there are purely cosmetic, fake, chemical/paint type methods used as well.

Originally, case-hardening was done to provide a hard surface with shock resistant core OR a hardened surface on a relatively inexpensive type of steel. The colors and form of the colors are a result of the method used. Color case has become such a traditional finish that there are purely cosmetic, fake, chemical/paint type methods used as well.

Sincerely,

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Re: Case-hardening ?

Mike Hunter does excellent case hardening, and far more traditional looking to my way of thinking. Check out the color on this Browning's hammer and lever that Mike did for me.

"Congressmen who willfully take actions during wartime that damage morale, and undermine the military are saboteurs and should be arrested, exiled or hanged"....President Abraham Lincoln

-

bdhold

Re: Case-hardening ?

case hardening was pack carburizing - packing the metal parts in a can of high grade carbon (coke - coal baked to remove impurities).

The can of parts is annealed in a furnace at 1800oF. The carbon content in the surface layer - case - increases making the case metal more hardenable than the softer (but tougher) core. Taken from the furnace, the parts are quenched in oil. It was the reaction of the oil, carbon residue and rapid oxdation of the hot parts (when exposed to the air from the carbon to the oil) that produced the case colors. The case hardening process would result in Rockwell C50+ hardness in the case vs. C30+ in the metal core.

yes, current case coloring is chemical etching - just color, not hardness.

Advantage of case hardening? You make the surface stronger and more scratch resistant, and moving/contacting/sliding parts will last longer.

Hobie, yes, if the metal were carburized and hardened through (i.e., no softer tougher core) and you dropped the gun, it would break.

You need that softer tough core to absorb shock and resist cracking

The can of parts is annealed in a furnace at 1800oF. The carbon content in the surface layer - case - increases making the case metal more hardenable than the softer (but tougher) core. Taken from the furnace, the parts are quenched in oil. It was the reaction of the oil, carbon residue and rapid oxdation of the hot parts (when exposed to the air from the carbon to the oil) that produced the case colors. The case hardening process would result in Rockwell C50+ hardness in the case vs. C30+ in the metal core.

yes, current case coloring is chemical etching - just color, not hardness.

Advantage of case hardening? You make the surface stronger and more scratch resistant, and moving/contacting/sliding parts will last longer.

Hobie, yes, if the metal were carburized and hardened through (i.e., no softer tougher core) and you dropped the gun, it would break.

You need that softer tough core to absorb shock and resist cracking

-

Nate Kiowa Jones

- Site Sponsor

- Posts: 2508

- Joined: Fri Sep 07, 2007 12:05 pm

- Location: Lampasas, Texas

- Contact:

Re: Case-hardening ?

Mike does my Color-case work. There are a lot of folks doing color-case hardening work but Mike and Turnbull are the only two I trust to do complicated parts like leveraction receivers. They know how to do it without warping them.Hobie wrote:Our own Mike Hunter does color-case as well.

Originally, case-hardening was done to provide a hard surface with shock resistant core OR a hardened surface on a relatively inexpensive type of steel. The colors and form of the colors are a result of the method used. Color case has become such a traditional finish that there are purely cosmetic, fake, chemical/paint type methods used as well.

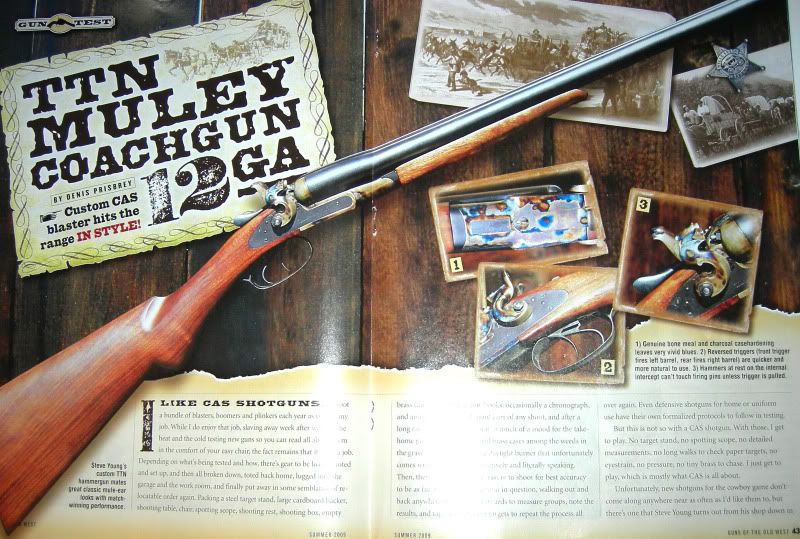

Mike has also done several of these SXS's for me. This gun was features in last years summer addition of the Guns of the Old West magazine.

Steve Young aka Nate Kiowa Jones Sass# 6765

Steve's Guns aka "Rossi 92 Specialists"

205 Antler lane

Lampasas, Texas 76550

http://www.stevesgunz.com

Email; steve@stevesgunz.com

Tel: 512-564-1015

Steve's Guns aka "Rossi 92 Specialists"

205 Antler lane

Lampasas, Texas 76550

http://www.stevesgunz.com

Email; steve@stevesgunz.com

Tel: 512-564-1015

Re: Case-hardening ?

I much prefer these examples of case hardening to some I've seen with the very bright blues and such. Some of it is just too flashy.

NRA Life Member

Re: Case-hardening ?

True color-case hardening, in whatever variation just makes me salivate. It may no longer be practical. It might be expensive. It might not be durable. I don't care. The paint is like lipstick. It can be forgotten or overlooked but it can never be the real thing.

Sincerely,

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

Hobie

"We are all travelers in the wilderness of this world, and the best that we find in our travels is an honest friend." Robert Louis Stevenson

-

Doc Hudson

- Member Emeritus

- Posts: 2277

- Joined: Mon Apr 02, 2007 9:22 pm

- Location: Crenshaw County, Alabama

Re: Case-hardening ?

Q:Why Case harden?

A: To make the metal somewhat stronger than it was before, think of it as an old-fashion version of heat treating.

The problem is that case hardening ins maily on the surface rather than a through and through treatment. Improperly performed, it can lead to brittleness and easy breakage.

Q: How to case harden?

A: #1Don't try it at home on the frame of a more or less modern weapon. To do a proper job of Color Case Hardening requires the use of some pretty toxic stuff and is at the very least as much an Art as a Science. If you have a firearm you want Color Case Hardened, send it to Doug Turnbull, it will be cheaper than replacing the gun after you screw it up.

Q: How to Case Harden?

A: #2 Here is how the old-timers case hardened small parts to repair a muzzle-loader.

Taken from page 505 of Disic Gun Works Catalog # 136

A: To make the metal somewhat stronger than it was before, think of it as an old-fashion version of heat treating.

The problem is that case hardening ins maily on the surface rather than a through and through treatment. Improperly performed, it can lead to brittleness and easy breakage.

Q: How to case harden?

A: #1Don't try it at home on the frame of a more or less modern weapon. To do a proper job of Color Case Hardening requires the use of some pretty toxic stuff and is at the very least as much an Art as a Science. If you have a firearm you want Color Case Hardened, send it to Doug Turnbull, it will be cheaper than replacing the gun after you screw it up.

Q: How to Case Harden?

A: #2 Here is how the old-timers case hardened small parts to repair a muzzle-loader.

Taken from page 505 of Disic Gun Works Catalog # 136

Plese note that the directions given in the DGW quote is for casehardening, not Color Casehardening. Color Casehardening is something for professionals to do, not amateurs.How to Caseharden a Frizzen the “Old” Way

The following is a formula sent to us by Mr. Ken Davison, Leslie, Arkansas on how to caseharden a frizzen and other small parts. He has a very quaint way ofto do this. Therefore, not to take anything away from his explanation, I am inserting it in the catalog as he wrote it.

First clean the part to be hardened then wrap it in leather, plain old leather, shoe leather, etc. Now cover the leather, [art and all with clay. If good clay isn’t at handsome household tinfoil wrapped around the leather and part works just as well, say maybe a tin can that can be closed somewhat around the leather and the part. Next you need a wood fire. A fireplace or a wood heater will do but not a oxygen-welding torch , or gas stove, etc. A electric kiln woked once, but it took about 4 hours while it usually takes only about 40 minutes. Put leather part and clay, or better yet tin can or tinfoil in the wood fire, let heat until part is red hot, for about 30 minutes. Take part out, still in its container and drop the whole thing in cold water. Try this yourselves and see. Put a few nails in with the part to run tests on. If done right you cant cut them with a file. Be sure to do all your filing before hardening as afterward it is pretty hard. By this method a mountain man could reharden his frizzen himself miles from any blacksmith. I haven't found any hardening to give a hotter spark or wear as well. I don’t have good data on how long a frizzen so hardened will continue to give a good spark as I have yet to wear one out. We once hardened the frizzen of a Tower flintlock pistol to the point the hardening met in the middle. The result ws an enormous shower of sparks and a shatteed frizzen, We learned fro this to only leave the parts in the fire for 1 hour at the most, 40 minutes is better. 30 minutes will do.

Sincerely,

Ken Davidson

Doc Hudson, OOF, IOFA, CSA, F&AM, SCV, NRA LIFE MEMBER, IDJRS #002, IDCT, King of Typoists

Amici familia ab lectio est

UNITE!

Amici familia ab lectio est

UNITE!

Re: Case-hardening ?

I also found this at http://www.gunreports.com ,look under special reports for case harden with Kesenit, lookunder special reports.

Last edited by tomtex on Wed Jun 16, 2010 12:15 pm, edited 1 time in total.

-

Mike Hunter

- Member Emeritus

- Posts: 285

- Joined: Thu Dec 20, 2007 6:28 pm

Re: Case-hardening ?

Lots of myths/inaccuracies surrounding true Case hardening and Color Case Hardening, hopefully I can dispel some of them.

Case Hardening has been around for a long time; several hundred years. It’s a way to make soft, low carbon Iron and steel a little more durable by adding carbon to the outer layer of steel.

Keep in mind that steel with less than .25% carbon is considered non hardening steel; there’s not enough carbon within the steel for the steel to be hardenable on its own. These steels are what are commonly referred to as Case Hardening Steels, or non hardening steels. Somme common steels are 1018, 12L14, 8620 etc, where the last two numbers denote the percentage of carbon.

Other steels with more than .25% carbon, such as 1095 (.95% carbon) and 4140 (.40% Carbon) are considered thru hardening steels, where the hardness goes all the way thru the steel.

We can add more carbon to the outer layer of mild steel several ways, the old traditional way was with pack hardening. Where the steel object was placed in a steel container, with compounds high in carbon and heated above the critical temperature. At this temperature these compounds would outgas carbon monoxide & carbon dioxide which would be absorbed by the metal, at a slow but consistent rate. Once the desired rate of penetration is achieved the steel is quickly quenched in water or oil to “lock in” the harder carbon layer.

What you have now is a piece of steel with a very hard, wear resistant but brittle outer shell, and a softer more shock resistant inner core. Which is ideal for certain gun parts.

So that’s case hardening in a nutshell; Color Case Hardening is the same, but now we have to introduce that beautiful mottled pattern, which if you haven’t noticed is different among firearm manufacturers of the time. Winchester is different than Colt, which is different from L.C.Smith etc.

All sorts of variables affect the colors: bone to wood ratio, type & size of the charcoal, quench temp, water temp, distance that you drop the parts, amount of air in the water, type of water; just changing one variable can change the entire look.

As I stated earlier; any steel with more than .25% carbon is considered thru hardening steel and should not be case hardened. It will case cracking, warping and uncertain/unequal heat treatment. I have heard of some folks that will CCH anything made of steel. My advice, run away … as quickly as you can.

Mike

Case Hardening has been around for a long time; several hundred years. It’s a way to make soft, low carbon Iron and steel a little more durable by adding carbon to the outer layer of steel.

Keep in mind that steel with less than .25% carbon is considered non hardening steel; there’s not enough carbon within the steel for the steel to be hardenable on its own. These steels are what are commonly referred to as Case Hardening Steels, or non hardening steels. Somme common steels are 1018, 12L14, 8620 etc, where the last two numbers denote the percentage of carbon.

Other steels with more than .25% carbon, such as 1095 (.95% carbon) and 4140 (.40% Carbon) are considered thru hardening steels, where the hardness goes all the way thru the steel.

We can add more carbon to the outer layer of mild steel several ways, the old traditional way was with pack hardening. Where the steel object was placed in a steel container, with compounds high in carbon and heated above the critical temperature. At this temperature these compounds would outgas carbon monoxide & carbon dioxide which would be absorbed by the metal, at a slow but consistent rate. Once the desired rate of penetration is achieved the steel is quickly quenched in water or oil to “lock in” the harder carbon layer.

What you have now is a piece of steel with a very hard, wear resistant but brittle outer shell, and a softer more shock resistant inner core. Which is ideal for certain gun parts.

So that’s case hardening in a nutshell; Color Case Hardening is the same, but now we have to introduce that beautiful mottled pattern, which if you haven’t noticed is different among firearm manufacturers of the time. Winchester is different than Colt, which is different from L.C.Smith etc.

All sorts of variables affect the colors: bone to wood ratio, type & size of the charcoal, quench temp, water temp, distance that you drop the parts, amount of air in the water, type of water; just changing one variable can change the entire look.

As I stated earlier; any steel with more than .25% carbon is considered thru hardening steel and should not be case hardened. It will case cracking, warping and uncertain/unequal heat treatment. I have heard of some folks that will CCH anything made of steel. My advice, run away … as quickly as you can.

Mike

-

Ben_Rumson

- Advanced Levergunner

- Posts: 2569

- Joined: Sat Sep 15, 2007 12:51 pm

Re: Case-hardening ?

Thanks Mike!

"IT IS MY OPINION, AND I AM CORRECT SO DON'T ARGUE, THE 99 SAVAGE IS THE FINEST RIFLE EVER MADE IN AMERICA."

WIL TERRY

WIL TERRY